Honeycomb aluminum foil price

Honeycomb aluminum foil is a honeycomb-shaped structure made of aluminum foil material, which has the advantages of light weight, high strength, corrosion resistance, and thermal insulation. It is commonly used in construction, aerospace, transportation, and other fields as a structural or insulation material.

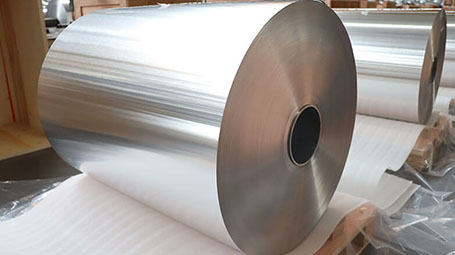

The manufacturing process of honeycomb aluminum foil includes cutting aluminum foil material into small pieces of a certain shape, and then bonding them together with an adhesive to form a honeycomb structure. This structure has high strength and stiffness, can withstand large external forces and pressures, and has good thermal insulation and heat insulation performance.

The honeycomb core is mostly made of 3004 aluminum foil, which is laminated into multiple layers and then unfolded into a regular honeycomb shape, used as the intermediate structure of aluminum honeycomb panels. The thickness of aluminum foil is 0.02-0.06mm, and the state is h18, h19. The aluminum honeycomb panel has different side lengths of 5mm, 6mm, 8mm, 10mm, and 12mm. Aluminum honeycomb panels are suitable for civil buildings, vehicle and ship decoration, etc. With the increase in market demand, the usage of 3004 honeycomb aluminum foil is also increasing.

3004-h19 honeycomb aluminum foil price

Advantages of 3004-h19 honeycomb aluminum foil

1. Excellent Mechanical Properties: 3004-H19 honeycomb aluminum foil has excellent tensile strength, yield strength, and impact toughness, able to withstand large external forces and pressures, and is not easily deformed or cracked.

2. Good Corrosion Resistance: Aluminum foil has good corrosion resistance, able to resist the corrosion of atmosphere, water, and chemicals, extending the service life of buildings.

3. Good Insulation Performance: The honeycomb structure can effectively prevent air flow, reduce heat transfer, and improve the insulation performance of buildings.

4. Easy to Process and Install: 3004-H19 honeycomb aluminum foil has good processability, can be cut, bent, and spliced according to design requirements, and is easy to install and fix.

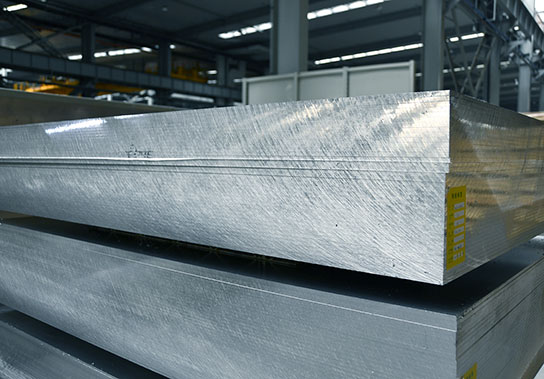

1.Equipped with a plate shape control instrument to monitor the plate shape in real-time; subsequent stretching and straightening processes ensure the plate shape is well-corrected, ensuring good aluminum foil plate shape, high flatness, and good plate shape accuracy.

2.Special oil removal equipment is used, with imported cleaning agents, ensuring the aluminum foil surface is free of oil stains, the adhesive is solid, and it is not easy to peel off, ensuring a long service life.

3.The company can produce aluminum foil substrates for 3004 honeycomb cores with thicknesses ranging from 0.02 to 0.06mm and various widths, with customized production, large production capacity, and short delivery cycles.

4. Direct sales from the 3004 honeycomb aluminum foil manufacturer, with prices lower than those of peers, inquiries can be made at +86-19337109479(WeChat/WhatsApp).