How is the quality of Mingtan blister aluminum foil?

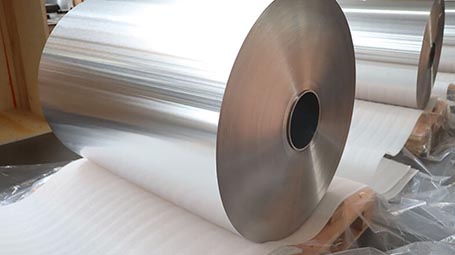

Mingtan Blister Aluminium Foil Quality

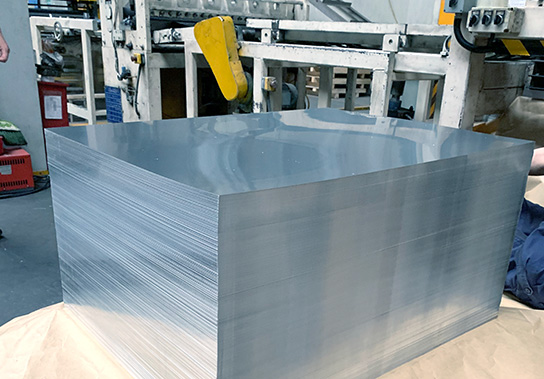

When it comes to pharmaceutical packaging materials, aluminum foil stands alone as the only metal option. It offers safety and odorless qualities, ensuring the protection of the enclosed contents. With its excellent conductivity, light-blocking properties, remarkable moisture resistance, gas barrier capabilities, and taste retention properties, aluminum foil is the most effective packaging material available for preserving the integrity of packaged items. As a result, it remains a packaging material that cannot be replaced.

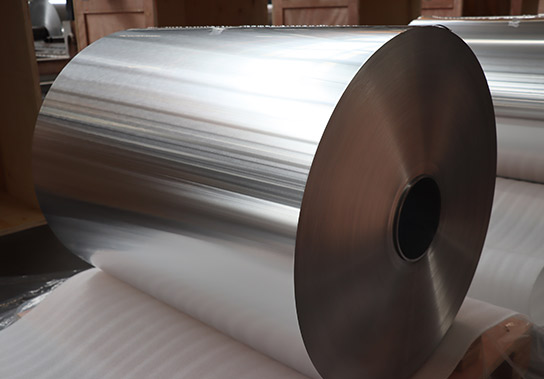

Mingtan Aluminum, a leading aluminum foil manufacturer , takes quality control very seriously. We conduct rigorous testing to ensure the highest standards of quality. PTP aluminum foil testing is a crucial step in the quality inspection of pharmaceutical packaging materials. PTP aluminum foil, a widely used material for pharmaceutical packaging, offers exceptional moisture and gas barrier properties, effectively safeguarding the quality and safety of medicines. It consists primarily of an aluminum foil base and a adhesive layer, which work together to provide superior protection. At Mingtai Aluminum, we pride ourselves on our commitment to quality and safety, ensuring that our products meet the highest standards in the industry.

PTP aluminum foil testing mainly involves the following aspects:

Material quality: Test the thickness, tensile strength, and elongation of the aluminum foil to ensure it meets the required standards.

Surface quality: Examine the surface of the aluminum foil for any defects, such as scratches, pinholes, or tears.

Adhesion strength: Test the adhesion strength between the aluminum foil and any adhesive used in the product.

Environmental resistance: Test the aluminum foil’s resistance to various environmental conditions, such as temperature, humidity, and corrosion.

Safety testing: Conduct tests to ensure the aluminum foil is non-toxic and meets all safety regulations.

Performance testing: Evaluate the aluminum foil’s performance in terms of its barrier properties, tensile strength, and other relevant characteristics.

By conducting these tests, we can ensure that the PTP aluminum foil meets the required quality standards and is suitable for its intended use.