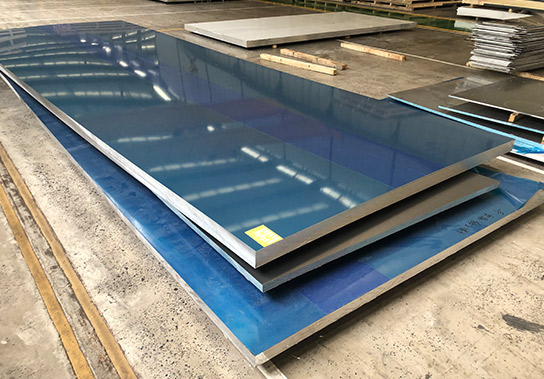

Medium thickness 1050 aluminum plate

Medium thickness 1050 aluminum plate

Introduction to Medium Thickness 1050 Aluminum Plate

The Medium thickness 1050 aluminum plate has emerged as a cornerstone in various industrial applications due to its exceptional properties and versatility. This aluminum alloy, known for its high purity and excellent electrical and thermal conductivity, is widely used in industries ranging from electronics to construction. Its medium thickness provides a balance between durability and ease of handling, making it a preferred choice for many manufacturers and engineers.

Applications of Medium Thickness 1050 Aluminum Plate

One of the standout features of the Medium thickness 1050 aluminum plate is its broad range of applications. In the electronics industry, it serves as a reliable material for heat sinks and electrical conductors due to its superior conductivity. In construction, its corrosion resistance and lightweight properties make it ideal for roofing and cladding. Additionally, the medium thickness ensures that it can be easily machined and formed, catering to a variety of custom fabrication needs.

Advantages of Medium Thickness 1050 Aluminum Plate

The Medium thickness 1050 aluminum plate offers several advantages that set it apart from other materials. Its high purity (99.5% aluminum) ensures excellent corrosion resistance, making it suitable for outdoor and marine environments. The medium thickness also provides a good balance between strength and flexibility, allowing for easier bending and shaping without compromising structural integrity. Furthermore, its lightweight nature reduces the overall weight of finished products, which is particularly beneficial in transportation and aerospace applications.

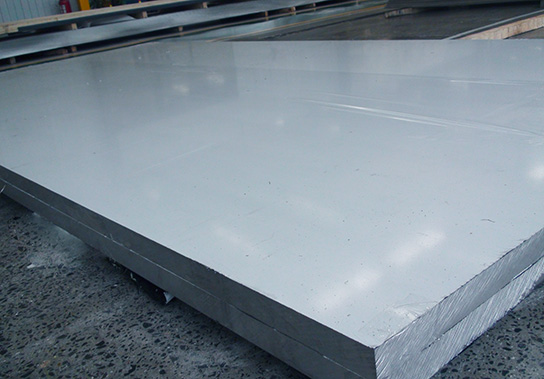

Manufacturing Process of Medium Thickness 1050 Aluminum Plate

The production of Medium thickness 1050 aluminum plate involves a meticulous process to ensure high quality and consistency. The raw aluminum is first melted and cast into ingots, which are then hot-rolled to achieve the desired thickness. Subsequent cold rolling and annealing processes refine the material, enhancing its mechanical properties and surface finish. This controlled manufacturing process results in a product that meets stringent industry standards and customer specifications.

Environmental Impact of Medium Thickness 1050 Aluminum Plate

In an era where sustainability is a growing concern, the Medium thickness 1050 aluminum plate stands out for its eco-friendly attributes. Aluminum is highly recyclable, and the 1050 alloy can be recycled without losing its properties. This makes it an environmentally responsible choice for industries looking to reduce their carbon footprint. Additionally, the energy-efficient manufacturing processes used to produce this aluminum plate contribute to lower greenhouse gas emissions.lightweight properties, and ease of customization.