What are the performance characteristics of aluminum discs?

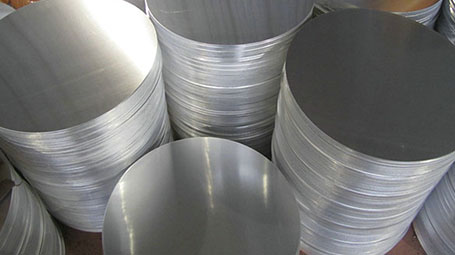

Introduction to aluminum discs:

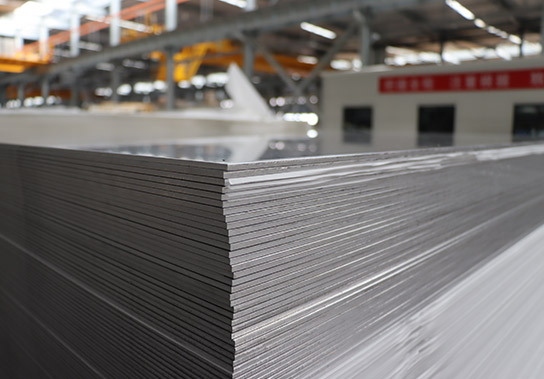

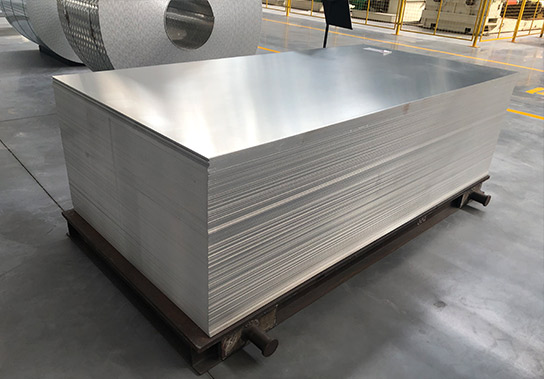

Mingtan Transportation New Materials has introduced advanced aluminum disc production equipment to effectively improve production efficiency and material utilization, so that the utilization rate of raw materials reaches more than 80%. The product range is complete, and covers 1, 2, 3, 5, 6, 7, and 8 series alloys. The products are widely used in the aluminum processing and manufacturing industry, such as stretched aluminum discs for cookers, stretched aluminum discs for lamps, aluminum discs for traffic signs, aluminum cans and tank heads, and other industries that require aluminum discs and aluminum discs.

Application of aluminum discs:

Aluminum discs are widely used in the aluminum processing and manufacturing industry, such as stretched aluminum discs for cookers, stretched aluminum discs for lamps, aluminum discs for traffic signs, aluminum cans and tank heads, and other industries that require aluminum discs and aluminum discs.

Performance characteristics of aluminum discs:

1. The surface performance of aluminum discs is good, ensuring no obvious scratches, oil stains, oxidation, black spots, etc.;

2. Good control of the grain size and elongation of the coil in the early stage ensures the excellent deep drawing and spinning performance of the aluminum disc, effectively avoiding the undesirable phenomena such as brushed lines, ruffles, and high ear-making rate that may appear in the later processing;

3. Strict control and inspection of the alloy, state, and performance of the coil to ensure the accuracy and diversity of the provided discs;

4. The classification of aluminum discs is detailed, and the accurate category can be selected according to the different uses and requirements of customers;

5. The product packaging is firm and meets the domestic sales and international export standards.