What is the best aluminum material for refrigeration equipment cooler housings?

3004 aluminum coil for refrigeration equipment cooler casing

With the continuous advancement of refrigeration technology and the increasing expansion of the refrigeration equipment market, the design and manufacturing of air coolers, the key components of refrigeration equipment, are also constantly being upgraded. Among them, the choice of shell material has an important impact on the performance and life of the air cooler. 3004 aluminum coil for refrigeration equipment cooler casing is excellent.

Characteristics of 3004 aluminum alloy

3004 aluminum alloy is a material with medium strength and good corrosion resistance. Its composition mainly includes aluminum, magnesium and a small amount of silicon, which gives it the following characteristics:

Good formability and processability: 3004 aluminum alloy is easy to perform various processing operations, such as bending, drawing, deep drawing, etc., which makes it easy to achieve complex structural designs when manufacturing cooler casings.

Excellent corrosion resistance: 3004 is an AL-Mn series alloy, which has good anti-rust properties and is not easy to corrode.

Good thermal conductivity: As a metal material, aluminum alloy has better thermal conductivity than many other materials, which helps the air cooler dissipate heat and improves its working efficiency.

Third, aluminum passivation: soak in aluminum passivation solution, the passivation time is 1-5 minutes, the purpose of passivation treatment is to form a dense and uniform coating on the surface of aluminum alloy.

Fourth, pure water soaking: 3 minutes. This process is a necessary process. Because the chloride ions in tap water usually adhere to the surface of aluminum parts.

Application of aluminum alloy in refrigeration equipment cooler casing

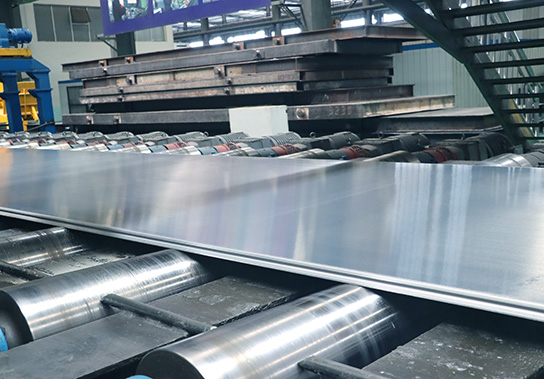

The main function of the refrigeration equipment air cooler housing is to protect the internal parts, withstand the impact of the external environment, and ensure the normal operation of the air cooler. With its unique properties, 3004 aluminum alloy plays an important role in the manufacture of air cooler casings for refrigeration equipment.

Refrigeration equipment usually needs to operate in various environments, and the corrosion resistance of 3004 aluminum alloy can ensure that the shell maintains good performance in harsh environments. This reduces equipment maintenance costs and improves equipment reliability. At the same time, aluminum alloy has a lower density, which allows refrigeration equipment to achieve lightweight design when using 3004 aluminum alloy to make the shell. It not only reduces the manufacturing cost of the equipment, but also helps to improve the transportation efficiency of the equipment and reduce energy consumption. .

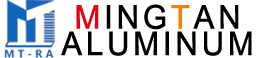

Mingtan Aluminum is a large-scale aluminum processing enterprise with relatively strong competitiveness in the industry, specializing in the production of 1-8 series aluminum plates, strips and foils. The company has advanced production equipment and processes, focuses on technology research and development and innovation, constantly optimizes production processes, and improves production efficiency and product quality. The 3004 aluminum coil used for air cooler casing has excellent quality and is very popular in the market.