What is the difference between 8611 and 3105 aluminum plates?

8011 vs 3105 Aluminum Sheet

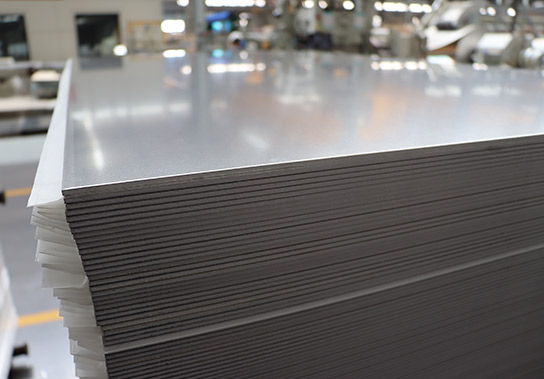

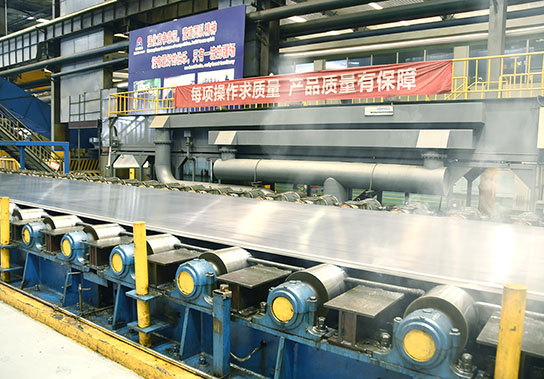

In the world of packaging, especially in industries like food and beverage, the choice of screw cap material plays a vital role in both functionality and aesthetics. The two most common materials used to manufacture aluminum screw caps are 8011 and 3105 aluminum sheets. These materials are popular for their unique properties, making them ideal for manufacturing durable, lightweight, corrosion-resistant screw caps. But what exactly makes these aluminum sheets stand out and why are they the top choice for manufacturers?

8011 vs 3105 Aluminum Sheet: What’s the Difference?

While 8011 and 3105 aluminum sheets are commonly used to produce aluminum screw caps, they each offer unique advantages. The 8011 alloy is known for its excellent formability and corrosion resistance, making it particularly suitable for screw caps that are exposed to moist or acidic beverages. It is commonly used in the food and beverage industry, where hygienic and long-lasting performance is critical.

On the other hand, 3105 aluminum sheet is slightly stronger and is often used in applications that require higher mechanical strength. This alloy is often the first choice for screw caps used on products that require a more robust seal or extra strength to withstand pressure. Despite the difference in strength, both alloys maintain excellent corrosion resistance and are lightweight, ensuring screw caps are both practical and cost-effective.

Customer Concerns: Durability, Cost, and Environmental Impact

When selecting the right material for aluminium screw caps, customers typically have a few key concerns, including durability, cost-effectiveness, and the environmental impact of the material. In terms of durability, both 8011 and 3105 aluminium sheets perform well, providing strong protection for the contents of the bottle or container. The corrosion resistance of both alloys also ensures that the screw caps retain their integrity over time, even in challenging conditions.

Cost is another significant factor for manufacturers. While 3105 aluminium may be slightly more expensive due to its enhanced strength, the price difference between the two alloys is generally minimal when purchased in bulk. Manufacturers should weigh the long-term benefits of each material and consider their specific needs when making a selection.

Environmental impact is an increasingly important issue for many customers, especially in industries that prioritize sustainability. Both 8011 and 3105 aluminium are recyclable, which makes them an eco-friendly choice compared to many other packaging materials. Aluminium is one of the most recycled materials globally, reducing the environmental footprint of aluminium screw cap production.